Manufacturers of packaging, insulation and other products made from recycled fibres are facing a shortage of raw materials due to the decline in newsprint and office paper volumes and increased demand for corrugated cardboard boxes. To provide them with an alternative source of quality fibre, Innofibre, the cellulosic-product innovation centre based in Trois-Rivières, has decided to launch two studies in partnership with the Carton Council of Canada (CCC) that could ultimately lead to the creation of new end markets for food and beverage cartons.

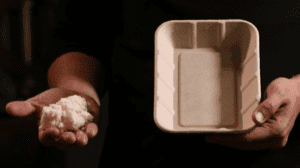

The first of these applied research projects focuses on moulded pulp packaging such as egg cartons and protective trays for electronic equipment, as well as thermoformed items often designed to replace plastic, such as food trays and single-use plates. Moulded pulp packaging is most often produced from unbleached pulp that is placed in moulds and then oven-dried. Thermoforming, on the other hand, typically uses bleached pulp and a high-temperature press to produce items with thinner, smoother and more rigid walls.

The Innofibre research team led by Eric Desnoes will produce the required pulp from post-consumer cartons on site and will then evaluate the production processes and physical properties of the resulting items, as well as their potential to be recycled in the future. Work will also be carried out to determine the properties of the polyal obtained during fibre separation (i.e., the substance that combines the aluminum and polyethylene in cartons) for industrial uses.

This study is largely funded by the CCC. The first results are expected in early 2024. According to Eric Desnoes, Québec and Canada have a number of fibre-based packaging manufacturers that could potentially benefit from it.

The second project aims to evaluate the use of shredded cartons in cellulose insulation products that are blown into building ceilings and walls. This insulation is traditionally made from newspaper. The study, led by Maude Tessier-Parenteau at Innofibre in collaboration with Aziz Laghdir at Serex, a technology transfer centre for forest-product processing based in Amqui, is currently awaiting funding confirmation. It could be up and running as early as the beginning of next year. A Québec cellulosic insulation manufacturer interested in the potential of this carton application is already involved.

For this and the packaging study, the CCC will supply the required quantity of carton bales, which it will obtain from a Québec MRF.

If these studies prove conclusive, it is hoped that they will inspire manufacturers in Québec and elsewhere, which could have a significant impact on the demand for carton bales.